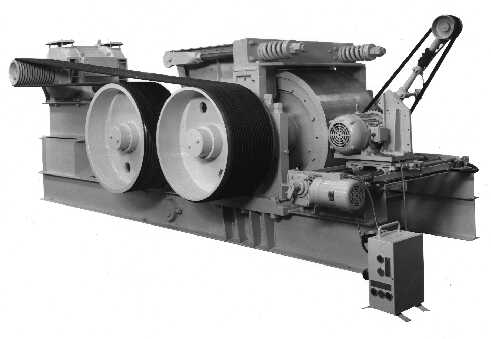

Shafts are 8"(203.2mm) diameter running on self aligning roller bearings, protected by double seals. To support the replaceable rims, two discs are keyed and shrunk on to each shaft, and accurately taper turned to receive the roll rims.

The roll rims are fitted to the taper at one end and located by a number of finger clamp plates. The opposite end is securely locked by means of a taper adaptor ring.

Rim material is abrasion resistant high alloy cast steel 2¼" (57.1 mm) thick.

Roll scrapers are hard faced steel with adjustment for roll clearance.

The base frame is fabricated mild steel. The bearing pedestals and frames are cast steel of robust dimensions. One roll is fixed and the other supported in pivoted arms which allow gap release for tramp metal etc. Gap release is either by spring load or rupture plates to client's choice. Roll gap is easily adjustable at pivot arms.

Single motor drive is effected by means of DUBL-V belts, 39CR is usually fitted with 75 HP and 24 CR with 50 HP.

To maintain the roll

faces for accurate crushing, these machines can

be supplied with belt type re-surfacing grinders. The

contact wheel

is driven by a 5 HP motor with automatic reversible traverse

driven by

a ½ HP motor.