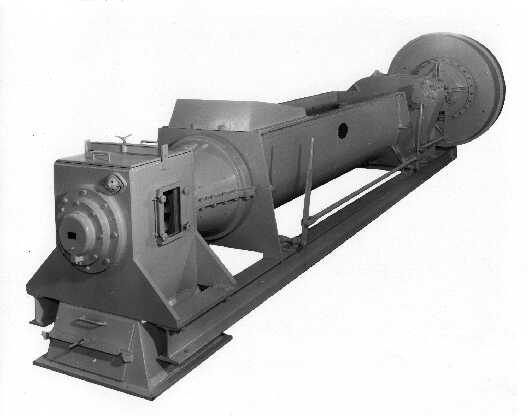

DE-AIRING HORIZONTAL EXTRUDERS WITH MIXER SEALERS

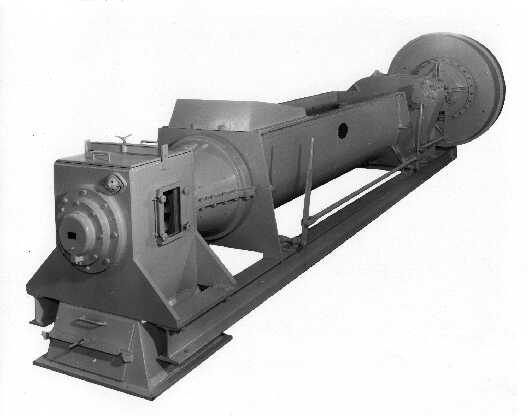

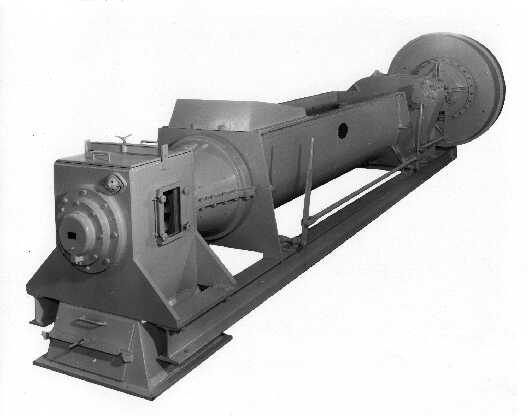

20/16 HMS HORIZONTAL EXTRUDER

CONSTRUCTION

Mainly mild steel fabrication designed for maximum rigidity and

torsional

stiffness.

DRIVE

Maximum 250HP motorized, vee belts and 30" (762mm) diameter disc

clutch.

SHAFTS

Auger Shaft - 7" (177.8mm) high tensile

Clutch Shaft - 4" (101.6mm) high tensile

GEARING

Machine cut, totally enclosed and running in pump circulated oil.

BEARINGS

Ball and roller throughout. Thrust bearing is SKF 29334.

AUGERS

27% Chrome material.

LINERS

All wearing faces are fitted with replaceable Ni-Hard liners.

VACUUM SEALING

All joint faces and liner bolts are 'O' ring sealed. Shaft

seals

are 'Tulip' packings.

BRICK DIES

Provision is made for double hung pressure lubricated brick die

and die

holders. Adjustment of 2½" (63.5mm) is also provided for variation

of compression length. The die holders are shear pin

protected.

PRODUCTION

Depending on the characteristics of the clay - 3" (75mm) bricks up

to 14,000

per hour.

Australian standard socketted pipe -

-

48" x 4" (1200 x 100mm) average 350 per hour

-

60" x 6" (1500 x 150mm) average 300 per hour

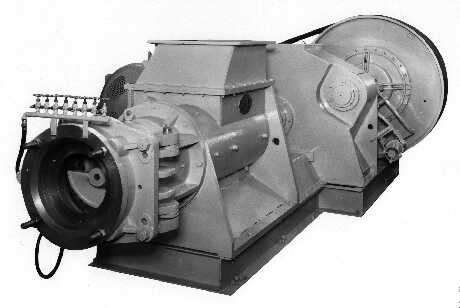

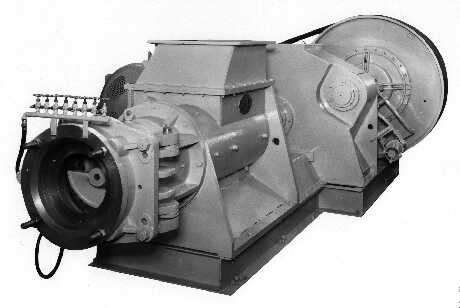

30 MS MIXER SEALER

This machine has two applications:-

-

As illustrated attached to the 20/16 MS Extruder supplying the

mixing,

shredding and vacuum sealing stage to the unit.

-

As a first stage mixing and shredding operation, not under

vacuum.

CONSTRUCTION

Mainly mild steel fabrication.

DRIVE

Maximum 175 HP motorized, vee belts and 30" (762mm) diameter disc

clutch.

SHAFTS

Knife shaft 7" (177.8mm) diameter.

Clutch shaft 4" (101.6mm) diameter

GEARING

Machine cut heat treated, totally enclosed and running in oil.

BEARINGS

Ball and roller throughout. Thrust bearing is SKF 29330.

KNIVES

Ni-HARD knives bolted to round shanks, key fitted into shaft

allowing for

easy adjustment of pitch.

SHREDDER SECTION

Tapered barrel with replaceable steel liner, Ni-HARD sealing

auger, sealing

core, sealing die and shredder plate.

Hardened alloy steel shredder knives.