| MODEL | VERTICAL BARREL DIAMETERS | HORIZONTAL BARREL DIAMETERS | DIAMETER RANGE OF PIPE PRODUCED | MOTOR HP REQUIREMENTS |

| 11/12 PSV | 11" (279.4mm) | 12" (304.8mm) | 3" (75mm) to 12" (300mm) | 75 to 100 |

| 13/12 PSV | 13" (330.2mm) | 12" (304.8mm) | 4" (100mm) to 18" (450mm) | 100 to125 |

| 13/13 EPSV | 13" (330.2mm) | 13" (330.2mm) | 4" (100mm) to 18" (450mm) | 125 to150 |

| 16/16 PSV | 16" (406.4mm) | 16" (406.4mm) | 6" (150mm) to 24" (600mm) | 125 to150 |

| 24/20 PSV | 24" (609.6mm) | 20" (508mm) | 12" (300mm) to 42" (1065mm) | 200 to250 |

| MODEL | BARREL DIAMETER | MIXER TUB | DIAMETER RANGE OF PIPE PRODUCED | MOTOR HP REQUIREMENTS FOR VERTICAL | MOTOR HP REQUIREMENTS FOR MIXER |

| 11 MSV | 11" (279.4mm) | 22" (558.8mm) wide 7'3" (2209.8mm) long | 3" (75mm) to 12" (300mm) | 75 | 60 |

| 13 MSV | 13" (330.2mm) | 22" (558.8mm) wide 7'3" (2209.8mm) long | 4" (100mm) to 18" (450mm) | 100 | 60 |

| 13 EMSV | 13" (330.2mm) | 22" (558.8mm) wide 7'3" (2209.8mm) long | 4" (100mm) to 18" (450mm) | 125 | 75 |

| 16 MSV | 16" (406.4mm) | 26" (660mm) wide 9'½" (2755.9mm) long | 6" (150mm) to 24" (600mm) | 150 | 100 |

| 24 MSV | 24" (609.6mm) | 30" (762mm) wide 11'3" (3429mm) long | 12" (300mm) to 42" (1065mm) | 200 | 125 |

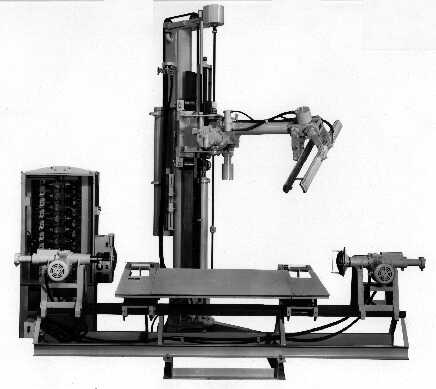

The extrusion from the De-airing Pipe Machine is brought down on the Automatic Pipe Finisher table to the predetermined length. The take-off cradles then take hold of the pipe, the pipe is cut at the die, the table drops to the bottom position and the pipe is taken away. It is rotated to the horizontal and lowered to the trimming rollers where both collar and spigot ends are trimmed and scored, then ejected towards an operator; an automatic rack loader or an automatic pallet loader. As soon as the pipe is clear of the extruder the table raises to start the extrusion of the next pipe.

Control is by electrically piloted pneumatic control.

Air consumption for each unit is :